What you should know before building a wine cellar in the UK

A & W Moore Wine Racks UK are often contacted after a wine cellar has been built and asked what they should do to rectify the faults that they have with their cellar because they have been given bad advice or used inexperienced companies. Below gives advice of how to avoid the pitfalls and the correct procedures. Adam and William Moore have been manufacturing wine racks longer than anyone else in the UK and have a wealth of experience.

There are four main factors to consider when building a wine cellar.

1) Humidity

2) Temperature

3) Light

4) Correct storage system

Humidity

Generally the British climate is never too dry to store wine and the need for a humidifier is not needed provided that the cellar does not have an excessive amount of ventilation. There are many more cellars that are too wet rather than too dry.

When building an underground cellar it is important that it is constructed to a grade 3 standard where no damp or seepage is acceptable.

Below are the grades for waterproofing underground structures:

Grade 1A – Seepage and damp areas from internal and external sources are tolerable if they don’t affect the intended use of the space.

Grade 1B – Seepage is not tolerable, but damp areas from both internal and external sources are (free water can’t enter, but damp patches can occur).

Grade 2 – Seepage is not acceptable, but damp areas may be tolerable if resulting from condensation or moisture in the air (this may require management measures).

Grade 3 – No seepage or damp is acceptable.

We have come across cases where the home owner did not take proper specialist advice and their builder was inexperienced in building under ground cellars/basements. The example below shows where a new build cellar was built to grade 1B. Grade 1B states that seepage of water is not tolerable, but damp areas from both internal and external sources are (free water can’t enter, but damp patches can occur). The problem with this standard is that when the water table rises considerably as it can during very heavy rain fall the damp patches turn to being extremely damp and wet. It is very difficult to construct grade 2 structure that does not turn into a Grade 1 structure after persistent heavy rain. The result is that a cellar with a humidity above 80%, mould is likely to form or grow on wooden surfaces and if wine was to be stored the labels and corks will grow mould as shown in the picture below.

If you have a cellar that is too damp there are many waterproofing products available that can be used to turn a very damp cellar into a perfectly usable one. The type and method will have to be assessed on an individual basis depending on the wall structure and the depth below ground level. The water pressure below ground rises the deeper the cellar is and this needs to be taken into account when deciding upon the remedy for a damp cellar. We have come across a case where a leaking cellar was successfully tanked, but after a period of heavy rain, the water pressure cracked and lifted the concrete floor.

Construction Chemicals Ltd provide a range of products that can be used to solve the problems of a damp cellar and they offer good advice on which product should be used. https://www.constructionchemicals.co.uk/ The products can be applied by a local builder. Other solutions involve lining the wall with a water proof membrane so that the water drains into a sump and a cellar pump to take away excess water.

Cellars that are built above ground level should be built with a vapour barrier to the floor, walls and ceiling and care should also be taken to ensure that they are well insulated.

Temperature

Wine cellars that are built below ground will often stay at a fairly constant temperature of 12-14˚ C provided there is no external heat source. The temperature of the ground is 12-14˚ C and the deeper the cellar, the more consistent the temperature is likely to be. If the room above the cellar has under floor heating this heat can be transmitted to the cellar. Likewise, if adjacent rooms are heated to living room temperatures this will affect the temperature of the cellar and a cellar conditioner might be needed. Insulation can be used to effectively reduce or eliminate the transfer of heat from other areas. Another source of heat in a cellar is if a wine fridge is installed to chill white wines or champagne. If a cellar conditioner is not needed a small amount of ventilation will be needed to stop the air in the cellar becoming stale. A cellar above ground with a north facing exterior wall will be considerably cooler than a cellar with a southerly aspect.

If a cellar conditioner is needed, you need to understand what a cellar conditioner does and how it works.

What is the difference between a standard or regular air conditioner and a proper wine cooling system?

Lower demand for temperature. Slower rate of cooling. All year running and humidification function.

Why should I buy a cellar conditioner rather than a regular/ standard air conditioner?

There are basically two types of cellar conditioner. One that sits in the wall and a split system where there is a unit on the cellar wall and another that is on the outside of the building.

First of all we should explain how a cellar conditioner works in a non technical format.

The cellar conditioners that sit in the wall have a fan that runs and circulates the air inside the cellar. The air entering the unit is cooled if it is above the desired temperature and the same air is returned to the cellar. There is a heat exchanger and the units operate within a 2˚C range so that the cooling side of the unit is not constantly being turned on and off. If the unit is set at 12˚ C it will run between 11-13˚C. The warmth created by the unit is then expelled out of the back of the unit. Some people think that the warm air coming out of the back of the unit is the same warm air that went into the front of the unit from the cellar which is incorrect. The air in the cellar is recirculated. As the air in the cellar is cooled it will produce a small amount of moisture. What tends to happen is that when the units are first turned on they will produce a small amount of water and then settle down to produce very little water if any, providing that the cellar has no damp problems and that the door has a proper seal and is not being continually opened. The units are not designed to be a dehumidifier for a damp cellar.

The split systems work in a very similar way except the warmth created by the unit in the cellar is transferred to a liquid which is pumped to the outside of the building and the heat is expelled into the atmosphere.

We have often been asked, particularly on new build projects, whether the company doing the air conditioning for the house can put a standard conditioning unit in and programme it to operate at 14˚ C . For example, Panasonic make a wall mounted PACi that can be programmed to operate at low temperatures. There has been problems with the standard units as the ones that we have used in our cellars have a special coating on the internal parts so that it helps to prevent corrosion. Cellars often have relatively high humidity levels compared with normal living accommodation. When moisture comes out of brick work or concrete it can form efflorescence salts. When this is combined with water it produces a chemical which can destroy the internal parts of the air conditioning unit.

The above picture shows efflorescence salts on the brick work. This was a new build cellar and the owner employed a company that did not have experience in fitting cellar conditioners. As the unit was a standard unit with no corrosion protection it failed after a few months of operation. After having a new cellar built it is a good idea to use a dehumidifier for a few weeks so the bricks and concrete can be thoroughly dried out. Often concrete will look and feel dry but it is still emitting moisture which can cause wood to warp and metal to rust. It is easy to tell when the cellar is properly dry as the dehumidifier will no longer be extracting water from the air.

We all know that salt mixed with water will cause metal to rust. Rusting metal is a product of a redox reaction as the metal is oxidated (loses electrons). Salt water speeds up this process by allowing electrons to move more freely. The salt water is more of a catalyst for the rust, because untreated metals are rusting at all times, even without the presence of salt.

The corrosion process is sped up when you introduce salt water to the formula. Salt water corrosion of metals happens faster than freshwater because of the increase presence of dissolved ions. These ions allow electrons to move faster on the metal, speeding up the formation of rust. Both steel and stainless steel metals are susceptible to corrosion.

Standard air conditioners also tend to dry the air in the cellar as when the air is cooled moisture is removed and they have a drain to take this out of the cellar. The result is that the air can become very dry and can damage the corks by drying them out. It is not uncommon for the moisture content to be reduced to 50% humidity which is to low for a wine cellar. Proper cellar conditioners such as the Fondis units retain the water so that it can be sent back into the cellar to maintain a reasonable humidity. If there is excess water in damp cellars the units do have a drain to remove the excess.

There is an article on the internet that suggest that some Danish oil used on wine racks causes problems with air conditioning units which is false. The Danish oil that A & W Moore Wine Racks UK use is a high quality oil with just over half Pure Tung Oil, made up with a low odour white spirit. The White spirit helps the oil penetrate into wood, and then evaporates off leaving the Tung Oil to dry in the wood. Once dry, Pure Tung Oil is an inert flexible solid which will not dissolve in water. It was used by the Chinese for hundreds of years for waterproofing ships. Tung Oil will not leach or taint in water when dry, and will therefore not release any acidic (or neutral) ions. We have EN-ISO toy safety certificates for both Pure Tung Oil and Bestwood Danish Oil. It is also food compliant.

Fondis Cellar conditioners

Concealed Friax unit, which vents through top and bottom

Friax unit through the wall

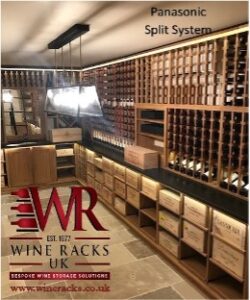

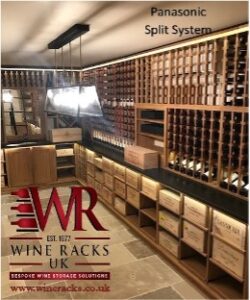

Panasonic Split System

For expert advice on cellar cooling please contact A & W Moore Wine Racks UK at info@wineracks.co.uk or Tel: 01159441434.

Light

Cellars should be dark and have no windows. Sun light contains UV rays which are harmful to wine. Lights should only used when you need to enter the cellar for retrieving your wine or re-stocking the cellar.

Storage System

Careful consideration should be given to the type and style of wine racks you need to look after your prized collection of wine. Stacking boxes of wine on top of each other is unwise as the wine that you will require first for drinking will be always at the bottom of the pile. Disturbing the wine on a regular basis can affect the wine. A well designed wine rack system that A & W Moore Wine Racks UK (Wineracks.co.uk) manufacture is well worth the investment. You will have to provide basic information on your wine collection.

The following information would useful to be able to obtain a design and quotation:

Do you need any storage for half or magnum bottles?

Do you need any storage for wooden cases and whether they are for 6 or 12 bottle cases?

Approximate quantity of standard bottles.

Any storage or display features for large format bottles.

Whether storage is needed for Krug, Dom Perignon or Bollinger bottles.

Storage for whiskey gin or brandy.

Storage for glasses and decanters.

Requirement for a sink.

Your budget: basic, medium or high end storage system.

Options available are:

Wood and galvanised steel wine racks https://wineracks.co.uk/traditional-wood-and-metal/

Solid pine wine racks https://wineracks.co.uk/solid-pine-wine-racks/

Solid oak wine racks https://wineracks.co.uk/solid-oak-wine-racks/

All metal wine racks https://wineracks.co.uk/vintage-view-metal-wine-racks/